The company

Your partner for shop fitting and interior design

We are a medium-sized company that sees its strengths in high production quality, highly trained and motivated employees and close co-operation with its customers. Since June 2000, we have been manufacturing aluminium profiles and counter fittings for professional shopfitting in Warstein, the headquarters of WAS, on an area of 3000 square metres.

From Warstein, we serve a growing number of customers throughout Europe through our sales offices in France, the Netherlands, Belgium, Poland and Austria.

Our aspiration to develop the perfect product for our customers’ applications is just as firmly anchored in our company DNA as the constant creation of innovative solutions. We not only rely on modern machines and systems, but also see the training and further education of our employees as the basis for our economic success. We are proud to be a recognised training company of the Arnsberg, Hellweg-Sauerland Chamber of Industry and Commerce and thus invest in the future of our company.

In addition, by constantly adapting our machinery in the areas of CNC machining and sawing technology, we ensure that we can meet delivery deadlines for shop fittings while maintaining the consistently high quality of the individual products. Thanks to high-performance CAD systems, our qualified designers are open to your requirements, so that there are no obstacles to successful cooperation with you.

Let us introduce ourselves: Get to know our systems and our company.

Construct

In order to be able to respond to your wishes in the best possible way, we work with you during the planning phase to find the best possible realisation of your ideas. The focus here is on ensuring that we can meet the requirements you place on your shop fittings with our aluminium profiles and counter fittings.

Read more

If you would like to design with our systems in advance, we will be happy to send you the appropriate DXF files.

Your plan serves as the basis for our work, from which we then create a proposal drawing and an offer for your enquiry.

If you are happy with this, the components for shop fittings will be manufactured on schedule in our factory, where our high-performance CAD and IT systems, combined with the experience of our employees, guarantee fast and uncomplicated processing.

Overall, functional design and hygiene requirements are our top priority when developing a wide range of products for the counter and shop fitting sector. These factors are tested in a variety of tests from the development phase through to series production.

Produce

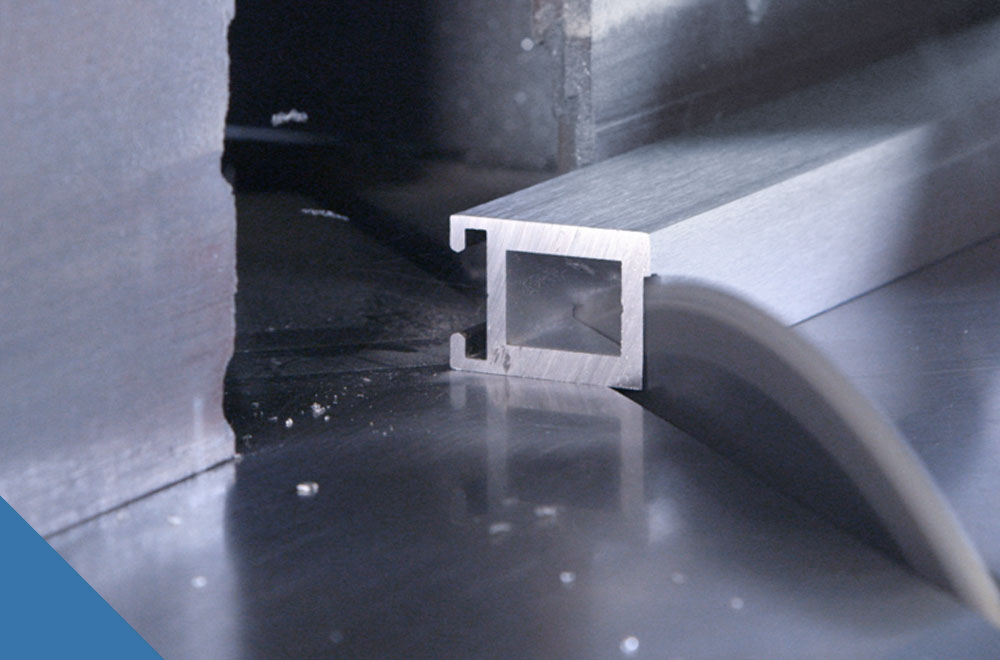

Our employees are familiar with all types of aluminium processing. This is why only fully developed products for shop fittings leave our premises. At the beginning of our production of components for sales counters and shop fittings, the various profiles are cut to size on modern saws and CNC automatic saws.

Read more

We then use our CNC machining centres to mill standard components as well as individual and customer-specific workpieces according to drawings.

Using various eccentric presses, we can perforate and shape aluminium profiles that are later used in shop fittings. The profiles are further processed on specially designed customised machines.

In our “grinding shop” production area, we can grind, brush and polish aluminium profiles and thus pre-treat them for high-quality surfaces.

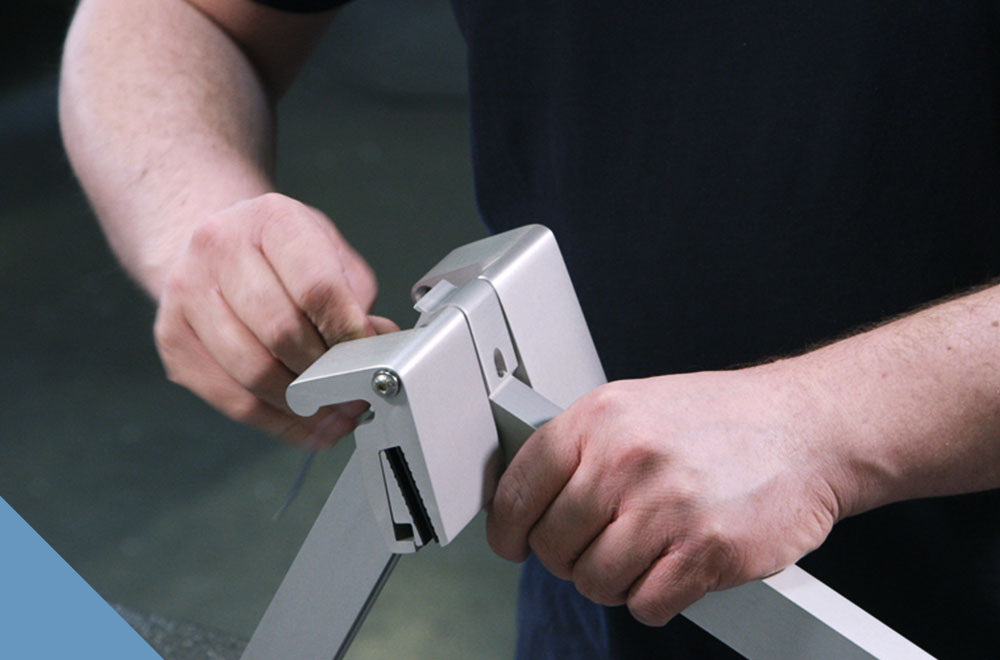

Assembly

The pre-assembly of series products for counter construction and shop fittings in our company means that you spend less time and labour on your property. We only use high-quality components, which increases the durability of our products.

Read more

We will be happy to fulfil your request for customised assortments. In addition to the drilling templates supplied, this also includes assembly instructions, precise labelling and marking of the individual order components and other aids that make it easier for you to assemble our products.

To ensure that your order arrives undamaged, it is then checked by our quality assurance department and dispatched in packaging suitable for transport.

Over 20 years of experience

Our company has been family-run for two generations.

Sustainability

A 160 kWh solar system ensures sustainable production.